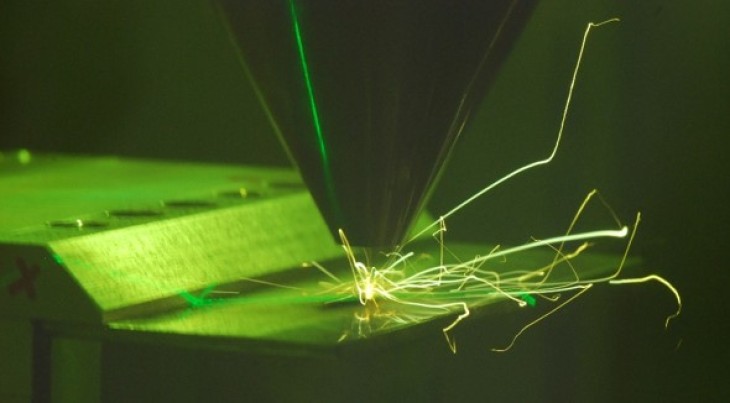

Laser metal deposition

Hereon/Josephin Enz

In laser metal deposition (LMD), structures are built up layer by laser by repeated local deposition and melting of metallic feedstock material, which can be in form of powder or wire. The heat source used to melt the material is a laser, which generally provides a higher laser power and a larger beam diameter compared to powder bed-based laser additive methods. Depending on the process variant, either the work piece or the laser processing head can be moved by a robot or another traversing unit. In addition, the material can be fed both laterally and coaxially to the laser beam. Laser metal deposition allows comparatively high deposition rates and a high degree of material utilisation, especially when wire feedstock is used to build the structures. Moreover, laser metal deposition can be fully automated.